Solar Meat Drying System:Redefining The Quality And Efficiency Of Meat Processing

In the meat processing industry, the drying process is a critical step that determines product quality, safety, and cost efficiency. Whether it's flavor-packed dried seafood, savory cured meats, or firm-textured beef jerky, traditional drying methods often face challenges like inconsistent quality, high energy consumption, and significant pollution risks. The emergence of solar-powered meat drying systems has revolutionized this sector with its innovative technology and superior performance, redefining both quality standards and operational efficiency in meat processing.

Traditional meat drying methods face multiple persistent challenges. Natural air-drying relies on weather conditions, making meat prone to moisture absorption and mold growth during rainy periods – a process that not only wastes raw materials but may also generate harmful substances. While firewood or coal drying is weather-resistant, it produces excessive smoke and dust that adhere to meat surfaces, compromising both appearance and texture while posing serious food safety risks. The high energy consumption further increases operational costs for manufacturers. Although electric drying equipment offers cleaner processing, the substantial electricity expenses create financial burdens for large-scale producers, ultimately eroding cost advantages over time. The emergence of solar-powered meat drying systems precisely addresses these industry pain points, providing meat processing enterprises with an innovative solution.

Excellent quality: restores the true flavor of meat and exceeds natural drying

For meat processing, product quality serves as the core competitive edge for enterprises in the market. The solar-powered meat drying system not only closely mimics natural drying principles but also surpasses them across multiple dimensions. During natural drying, meat exposed to air for extended periods becomes susceptible to contamination from dust, insects, and microorganisms. Additionally, temperature and humidity control proves challenging, resulting in uneven moisture distribution and inconsistent texture. By creating a sealed drying environment, this system effectively blocks external contaminants, ensuring meat undergoes the entire drying process in a clean and hygienic setting.

More importantly, this system can precisely regulate drying temperature and humidity according to the characteristics of different meats. Taking seafood products like squid and dried shrimp as examples, these items require strict temperature control. Excessively high temperatures may cause meat hardening and nutrient loss, while insufficient heat could prolong drying time and increase spoilage risks. The solar-powered meat drying system intelligently maintains optimal temperature ranges for seafood processing, ensuring final products retain tender texture, rich nutrients, and vibrant colors resembling freshly caught catches. For cured meats, traditional methods often result in dry exterior and moist interior, compromising flavor and shelf life. The solar system achieves uniform drying that preserves moderate moisture content throughout, producing savory, aromatic, and full-bodied textures. During beef jerky drying, the critical process involves locking in proteins and amino acids. The system's slow, steady operation maximizes nutrient retention, yielding clear-textured, chewy jerky with authentic beef aroma.

Safety and environmental protection: zero pollution drying, protect ecology and health

In today's world where environmental protection is increasingly embraced, corporate production methods not only impact their own sustainable development but also shoulder significant social responsibilities. The solar-powered meat drying system utilizes sunlight as its primary energy source, converting solar energy into thermal energy for drying operations. Throughout the process, it produces no smoke, dust, or harmful gases, truly realizing a "smoke-free, dust-free, and safety hazard-free" green drying model.

From a food safety perspective, traditional drying methods using firewood or coal produce harmful gases like carbon monoxide and sulfur dioxide. Additionally, incomplete combustion generates tar-like substances that seep into meat through air circulation. These contaminants may pose health risks to consumers. In contrast, solar-powered meat drying systems emit zero pollutants throughout the process. Meat remains completely free from harmful substances during drying, ensuring food safety at its source and giving consumers peace of mind when enjoying their meals.

From the perspective of ecological and environmental protection, the promotion and application of this system has effectively reduced traditional drying methods' reliance on fossil fuels, lowered greenhouse gas emissions such as carbon dioxide, and contributed to mitigating global warming. Simultaneously, it avoids deforestation caused by firewood drying practices, protects ecosystems, and achieves a win-win situation for economic and ecological benefits. For processing enterprises, adopting solar-powered meat drying systems can also enhance corporate image, earn consumer trust and market recognition, thereby laying a solid foundation for long-term development.

Cost advantage: Sunshine as the source, cost reduction and efficiency can be seen

Cost control is an important link for enterprises to enhance market competitiveness, especially in the meat processing industry, raw material costs and energy costs account for a large part of enterprise operating costs. Solar meat drying system with its unique energy utilization mode brings significant cost advantages for enterprises.

This system operates on the principle of "sunlight as the source and air as the medium". Solar energy, being an inexhaustible clean energy source, eliminates procurement costs for enterprises, significantly reducing energy expenses. Compared to traditional electric drying equipment, solar-powered meat drying systems require minimal maintenance costs during operation with virtually no additional energy expenditures. Statistics show that a medium-sized solar meat dryer can save companies tens of thousands of yuan annually in electricity costs. For large-scale processing enterprises, the cost-saving effect becomes even more pronounced.

Meanwhile, the solar-powered meat drying system operates on a "demand-driven heating" model. Through intelligent control systems that dynamically adjust thermal energy supply according to actual drying requirements, it effectively prevents energy waste. Traditional drying methods—whether wood-fired or electric—often suffer from imbalanced energy supply and low efficiency. In contrast, this solar-powered system precisely matches drying needs to maximize energy utilization, significantly reducing production costs. Additionally, its extended service life, simplified maintenance procedures, and lower upkeep expenses enable long-term operational value creation for businesses, thereby enhancing profitability.

Scientific and reasonable: digital sensing technology, precise control of the whole drying process

In modern production processes, technology serves as the core driving force for enhancing product quality and efficiency. The solar-powered meat drying system incorporates advanced digital sensing technology to achieve precise control over the drying process, ensuring each batch of meat products meets optimal quality standards.

The system is equipped with high-precision temperature, humidity, and weight sensors that continuously monitor real-time data including chamber temperatures, humidity levels, and meat weight variations. This data is transmitted to an intelligent control system which automatically adjusts the solar panels 'thermal efficiency, ventilation rates, and dehumidification capacity based on preset drying parameters and real-time measurements, enabling dynamic process management. For example, when overheating is detected, the system reduces solar panel energy input while increasing ventilation to lower temperatures. Similarly, if the meat's moisture content meets predetermined standards, the system automatically halts drying operations to prevent quality degradation caused by over-drying.

The application of digital sensing technology not only ensures premium meat quality in color, texture, and flavor, but also achieves automated and intelligent drying processes. This reduces manual operations, lowers labor costs, and minimizes human error. Traditional drying methods require workers to constantly monitor conditions and manually adjust parameters like temperature and humidity, which not only increases physical strain but also makes precise parameter control challenging. In contrast, the solar-powered meat drying system enables "unmanned" intelligent operation. Workers simply need to set parameters via a control panel, after which the system automatically completes the entire drying process. This significantly boosts production efficiency while ensuring consistent quality across every batch of products.

Whether it's aquaculture and seafood processing plants, cured meat manufacturers, or beef jerky workshops, solar-powered meat drying systems excel with their premium quality, eco-friendly design, cost efficiency, and scientific precision to meet diverse industry needs. As solar technology continues to evolve, these systems will enhance operational performance and expand applications, injecting fresh momentum into the meat processing sector's high-quality development. This technological advancement propels the industry toward greener, more efficient, and smarter manufacturing practices, ultimately delivering consumers premium-quality, safe, and wholesome meat products.

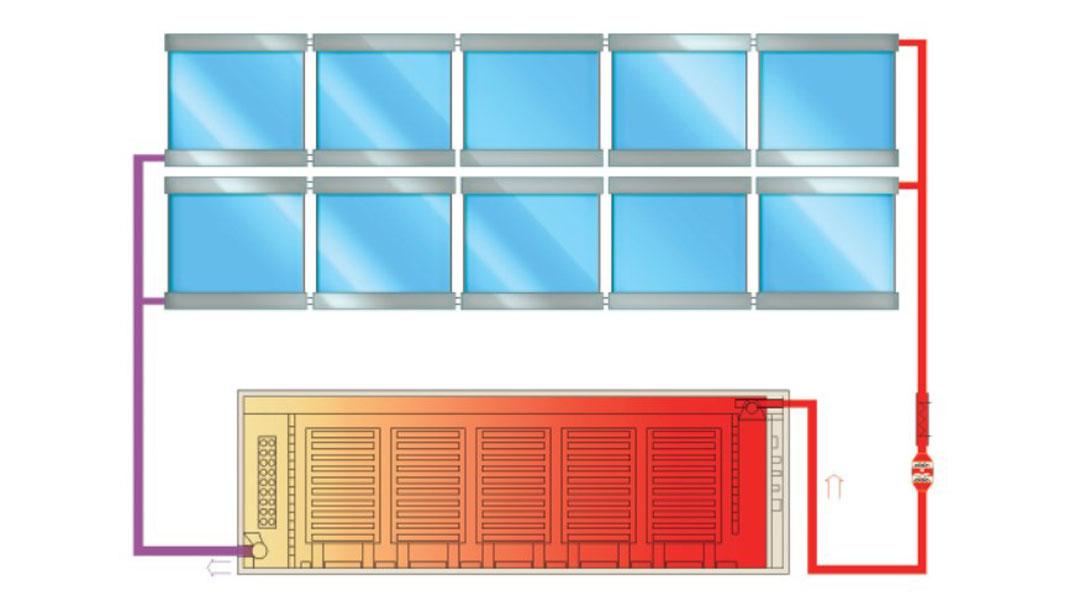

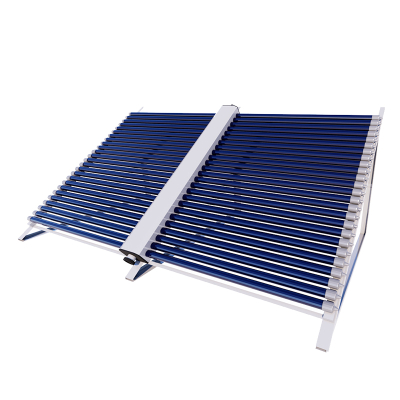

System operation schematic diagram